|

::: Company »

::: Products »

::: Events »

::: Archive »

::: Contact us »

|

::: NT-206 :::

Multifunctional scanning probe

microscope

(atomic force microscope) DESCRIPTION

Multifunctional scanning probe

Embedded videosystem in combination with motorized XY micropositioning stage provide convenient tuning of the instrument and its fine targeting onto the features on the sample surface. All that dramatically enhances the instrument's functionality when researching micro- and nanosize objects. To meet requirements of specific research tasks, AFM NT-206 can include specialized changeable probe holders for microtribometry and adhesiometry or for nanoindentation. FEATURES

* Before

measurements, the probe can be positioned to necessary place over the sample with

help of automated motorized stage. To provide monitoring for the scan area and

objects below the probe, the instrument embeds a videosystem allowing to watch

the probe motion over the sample surface. Videosystem and the motorized stage

for the probe positioning over sample are included in base set by default. A combination

of these two options allows rather flexible selection of objects to be measured

on the sample surface at direct visual monitoring by the opeartor.

DELIVERY SET

SOFTWARE

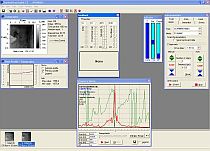

The control software provides all preliminary tunings and settings necessary for the AFM operation: visual control over the laser-beam detection system adjustment, tuning of the cantilever oscillations (in dynamic modes), feed-back system adjusting, sample positioning under the probe and sample approach to the probe before measurements and removal after the measurements. A full-field or any reduced area within the full field of the scanner can be selected for measurements. Operator can watch any combination of acquired AFM/LFM images in data visualization window or switch to look at them in one window. Additionally, profile of currenly acquired line can be monitored as well. Acquired data are saved in files of special format that can be then processed, visualised (in 2-D and 3-D presentation) and analysed with a specialized software package SurfaceView or SurfaceXplorer. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Control software for AFM NT-206 SurfaceScan

is a 32-bit Windows application.

Control software for AFM NT-206 SurfaceScan

is a 32-bit Windows application.